2021 Best Autolive Production System

Autoliv is a Swedish company and a safety supplier for multiple car manufacturers worldwide. Autoliv production system is based on innovation and development of advanced safety products. Autoliv uses continuous improvements and customer satisfaction to become a leader in the market. The company developed a training strategy based on knowledge sharing and accumulation in all companies’ production sites. The company provides high-quality products that are delivered on time, safer products, a good work environment for its employees, and achieves higher profits.

The company uses different tools of total quality management to achieve these goals. A report provided by the company shows multiple methods used by the company and how Autoliv combines other methods together with Total quality management. Autoliv represents a good example of how combining TQM together with other quality methods achieve great results. This allows Autoliv to hold a leader position on the market.

Autoliv production system, A mixture of different methods.

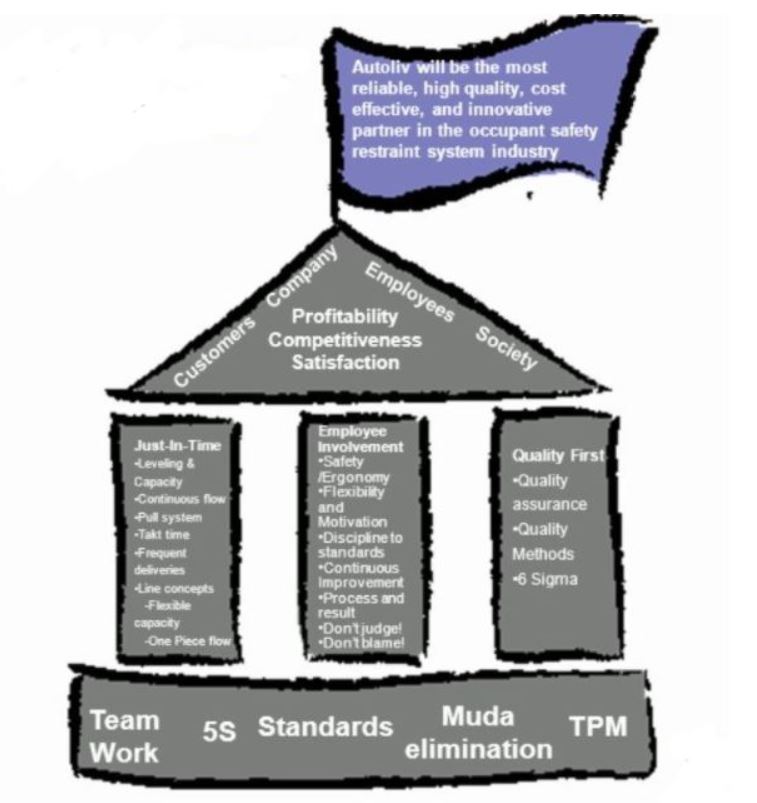

The method used by Autoliv is a combination of different methods and is named house of quality.

- The four foundations are: Team work, 5 S standards of housekeeping, Muda elimination and total productive maintenance.

- The three pillars are Just in time, Employee involvement and quality first.

- The roof is the purpose.

Autoliv production system has 4 foundations:

- 1st Foundation, Team-work: Team-work is the first foundation of the Autoliv production system, sharing results and experiences increases employees’ commitment. Team-work is also the most efficient way to solve problems and to achieve results. Autoliv uses the quality circle, which is a team coming from several departments. This team understands problems and offers solutions and follow up.

- 2nd Foundation, 5 S standards: it is a rigorous Japanese method of housekeeping. It maintains a clean and safe working environment.

- 3rd Foundation, Muda elimination or waste elimination: increase value-added activities (assembly of components) and reduce non-value added activities (transporting components). Reduce overproduction, defects, materials movements, delays, waiting for materials or previous processes. and unnecessary motions.

- 4th Foundation, TPM (Total productive maintenance): it is an innovative approach of maintenance that prevents breakdown and promotes autonomous operator maintenance through day-to-day activities involving the total workforce. It encourages employees to do periodical maintenance, record equipment performance.

The three pillars of APS house are

- 1st Pillar Just-In-Time: The objective of Just-In-Time is to have a lean manufacturing process that continuously, with cost efficiency, produces quality products at the right quantity to meet customer demand in the required time.

- 2nd pillar Quality First: It is another pillar of the Autoliv production system. In the quality first pillar, we have three elements. The rules for quality in Autoliv are: no reception of poor quality of materials from suppliers, no production of poor quality products, no shipment of poor quality products.

- Quality Assurance

- Quality Methods

- 6 Sigma

- 3rd Pillar Employee Involvement: The most important pillar of Autoliv house is Employee Involvement. Employee Involvement is at the centre of the Autoliv production system. Everyone has a role to play and everyone benefits. Employees are the most valuable resource for the company. The success of the business is dependent on the planning, control and improvement of all elements of the business and this can only be done by people. Every employee has knowledge and experience which may provide the key to solving a challenging problem.

The roof, the Purpose:

Now that we have built our pillars, we can put the roof on our house. The roof represents our purpose and is supported by the foundation and pillars. The purpose of the Autoliv production system is to meet the needs of customers and employees to ensure the success of our company and improve society. The Autoliv production method is cost improvement oriented. A rigorous application of APS will keep the Competitiveness for Autoliv.