TQM and Circular Economy

The increasing consumption level has not only caused negative impacts such as increased waste, but it has also resulted in the increase of the price of raw materials. Companies need to find alternatives to reduce the costs of primary products and of used products in a factory, while reducing waste at all production stages. By eliminating waste, a company can reduce costs, protect the environment, increase its profit, develop its activity, respect business ethics, and become responsible toward the environment, (Barbaritano et al. (2019), Riszos et al. (2015)).

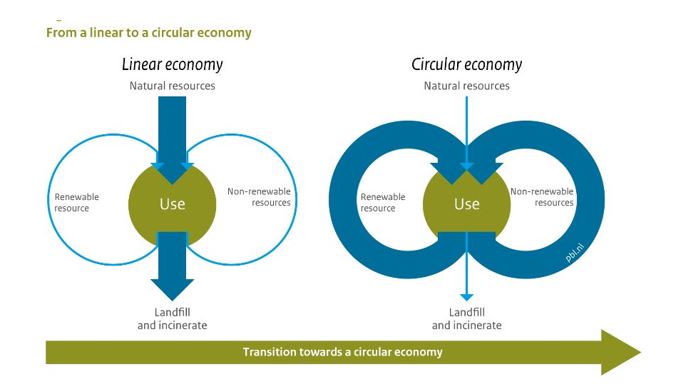

Also, the circular economy is an economic system of exchange and production which, at all stages of the life cycle of products (goods and services), aims to increase the efficiency of the use of resources and reduce the impact on the environment while developing the well-being of individuals. Thus, the circular economy also aims to drastically reduce the waste of resources. This concept gained significant momentum worldwide. The old linear model ‘take – make – dispose’ is no more able to meet sustainable challenges.From Linear economy to a circular economy. Source: PBL 2016.

There is an effort to reduce waste to apply circular economy principles in order to achieve sustainable development goals and to solve environmental problems, Ghisellini, & Ulgiati (2020). However, there are a lot of efforts that need to be done at the political level to encourage a circular economy in terms of regulation and incentives, Jawahir and Bradley (2016).

Circular economy principles from 3R to 10R

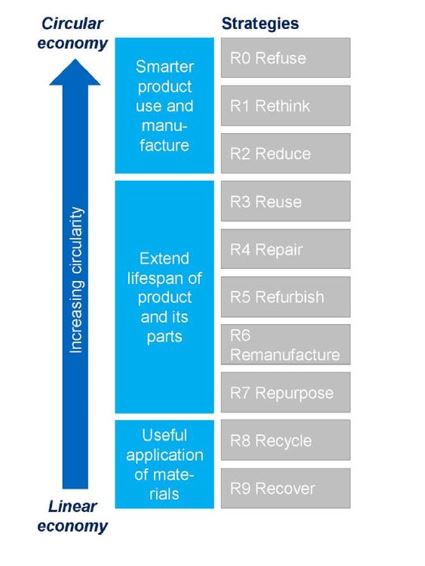

Historically, the circular economy concept was based only on 3R principles: Reduce, Reuse and Recycle, (King et al (2006), Brennan et al. (2015); Ghisellini et al. (2016)). It aimed first to reduce use of natural resources, producing minimum pollutions, emissions and wastes. This concept evolved later to be based on the 4Rs, according to the European Union (EU) Waste Framework Directive, European Commission (2008) introducing ‘Recover’ as the fourth R. Subsequently, other new framework appeared the 6Rs, Sihvonen and Ritola (2015) or even 10Rs, (van Buren et al. (2016), Potting et al. (2017), Kirchherr et al. (2017)).10 R. Source: Kirchherr et al. (2017)

- R0 Refuse: make product redundant by abandoning its function or by offering the same function with a radically different product.

- R1 Rethink: make product use more intensive (e.g. by sharing product)

- R2 Reduction: the aim is to reduce the environmental impact in terms of lower resource use, lower waste and emissions during product life cycle, Dieterle et al. (2018). In order to achieve this, there should be a focus on product design, avoiding obsolescence by extending product life cycle.

- R3 Reuse: consists of reusing the product like it is, or its components as spare; this aims to reduce the usage of new materials in order to produce newer products and components. Using similar products will be cheaper for the end user, as an example the growing market of car spare parts in Europe.

- R4 Repair: repair and maintenance of defective products, so it can be used with its original function.

- R5 Refurbish: is the process of collecting products at the end of the use stage, disassembling, sorting and cleaning for utilization in subsequent life-cycles of the product.

- R6 Remanufacture: involves the re-processing of already used products for restoration to their original state or a like-new form through the reuse of as many parts as possible without loss of functionality. This is widely common where many German companies remanufactured engines of Mercedes or BMW. This activity generates a lot of profits for these companies, because the engine looks brand new thanks to this process.

- R7 Repurpose: use discarded product or its part in a new product with a different function.

- R8 Recycle: process materials to obtain the same high grade or low grade (lower quality) product.

- R9 Recover: incineration of material with energy recovery

Application of total quality management allows the company to achieve these goals. Circular economy is aligned with total quality management objectives. It is an innovative way to reduce costs, increase profits, provide quality products and reduce the impact on the environment, (Dahlgaard and Dahlgaard‐Park (2006), Perey et al. (2018), Joiner TA (2007), Riszos et al. (2015), Barbaritano et al. (2019)).

In fact, circular economy and total quality management aim both to reduce or eliminate waste by reusing resources, (Dahlgaard and Dahlgaard‐Park (2006), Perey et al. (2018)). Circular economy states that taking part in sustainable practices does not mean a reduction in the quality of the product. Circular economy, however, increases income and provides extra revenues for companies while providing good quality products, Joiner TA (2007).

Furthermore, top management commitment is important to achieve circular economy, Riszos et al. (2015). Companies are generally willing to adopt circular economy practices, Bradford & Fraser (2007); the manager has power on strategic decisions of the company, and has the willingness to adopt or not circular economy; the presence of TQM culture enables circular economy practices adoption, where there is support of top management, (Riszos et al. (2015), Barbaritano et al. (2019)). In sum, circular economy is more profitable and sustainable than the conventional economic system.

In order to achieve circular economy goals, quality education and training for employees is an asset. In his study, Riszos et al. (2015) highlighted the importance of technical skills in adopting circular economy. Some companies do not have the technical capacity to identify, assess and implement more advanced technical options that would enable them to reduce their environmental impacts while realising cost savings; however, companies already implementing TQM have training as a priority making the adoption of